In planning a modification or expansion of your batching plant we leave nothing to chance and we are not wasting any millimeter of space.

With the Pemat 3D-scan technology, we scan the inside and outside of your plant in all details so we can rebuild it on the computer. Your future plant will be created in the virtual reality, that way you can inspect and test it – before even the modification has begun.

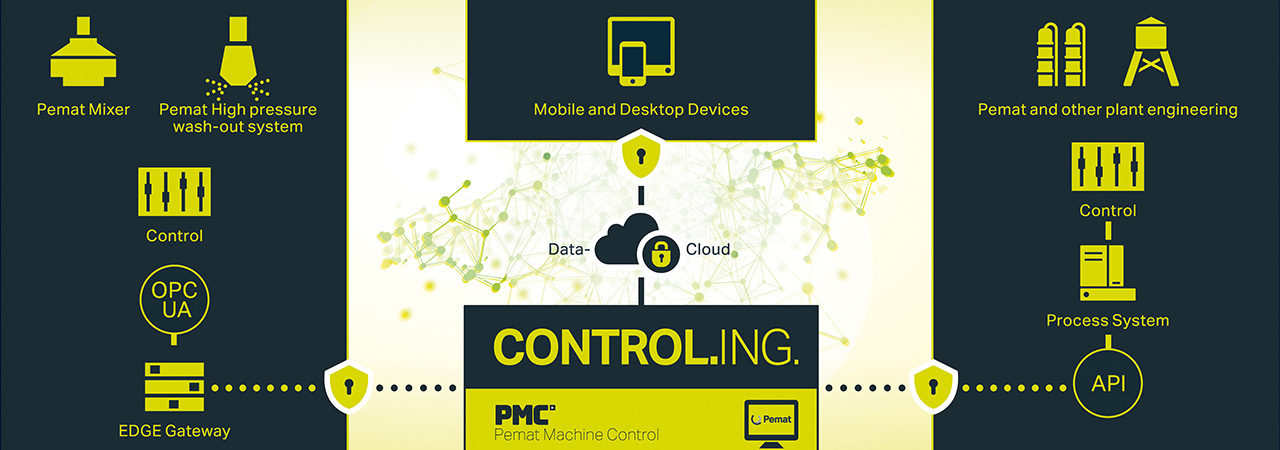

Not always on-site, but still everything under control!

With the PMC – the Pemat machine control – for platform-independent remote access to machine- (mixer) and plant datas (concrete plant) via computer, smartphone and tablet-pc.

Immerse yourself in a new world of product presentation and

make your purchase decision in the third dimension.

The new dimension also opens the door to inspect a mixing plant in virtual reality. You can move freely and look at the

products inside as well.

The discontinuous and independently controlled

whirler technology of Pemat

The discontinuous whirler technology of Pemat

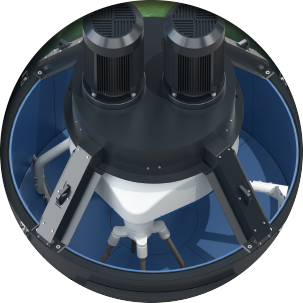

Concrete production nowadays places the greatest quality requirements on mechanical equipment. The homogeneity of the mixing process and the shortest mixing times are indispensable factors for economically viable mixing of the best possible quality. The Pemat Planetary mixer with addi-tional whirler (patented) provides you the ideal equipment for handling practically any task.

Advantages of the discontinuous

whirler technology of Pemat:

- Good distribution of the mix including fine grained materials

- Fast homogenisation

- Accurate repetition

- High energy efficiency

Discontinuous whirler technology

Example of planetary mixer PMPR

The independently controlled whirler technology of Pemat

Recipes, aggregates, admixtures and colour are increasingly innovative and specialised. To get the best possible results they need to be mixed perfectly. This places the highest possible demands on a mixer which the PMPM surpasses in all respects. It sets a completely new standard for the quality of mixing results and reveals to the future for mixing technology.

Advantages of the independently controlled

whirler technology of Pemat:

- Excellent distribution of the mix including fine grained materials

- Ultra-fast homogenisation

- The greatest possible repetition

- Very high energy efficiency

Independently controlled whirler technology

Example of multimix planetary PMPM

whirler technology