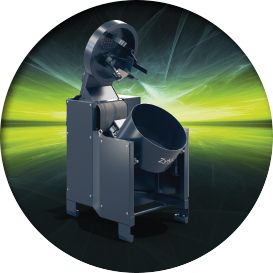

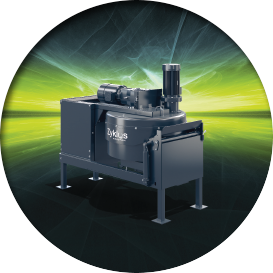

Zyklos Rotating Pan Mixer from Pemat

A lot of performance in a very small space

We produce Rotating Pan Mixer for ceramic compounds, refractory compounds, abrasives, chemical products, glass, floorings, concrete and roof tiles.

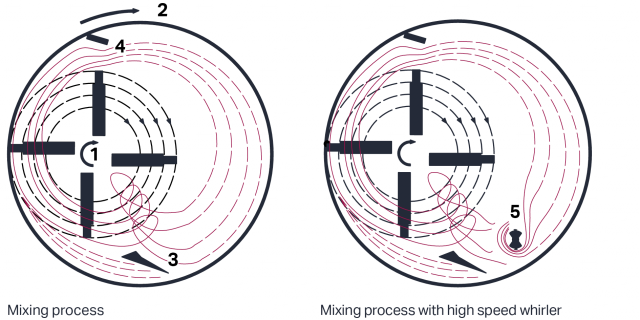

Mixing performance is based on the uniflow system

The offset mixing star [1] rotates synchronously with the mixing pan [2] thus producing high levels of shearing effect and kinetic energy release. Due to the high relative velocity of the batch a homogeneous mixture is quickly achieved. Statically mounted mixing tools [3] [4] on the tilting arm effect a horizontal and vertical rearrangement within the batch.

A wall scraper [4] continuously removes batch residues from the pan wall and deposits this back into the batch flow stream.

The pressure of the batch against the wall and the bottom of the mixing pan, produced by the mixing tools, makes the mixing pan turn co-currently without any extra drive. This rotation can be supported – if necessary – by an additional pan drive.

In order to intensify the mixing process, we could supply high speed whirlers [5] as an option.

Drive unit

- Sturdy gear motors

- Speed control (optional)

Mixing tools / whirler

- When closing the tilting arm, all driven mixing tools are started automatically and switched off again when opening

- Static tools additionally layer the material

- Scraper for cleaning the pan inner wall during mixing

- Fast rotating whirler can be retrofitted, also with speed control

- The Mixing Star is available in various materials and designs

Mixing pan

- Available in various materials

- Bolted wear linings possible

- The turn of the mixing pan is produced by friction of the batch. This rotation can be supported by an additional pan drive

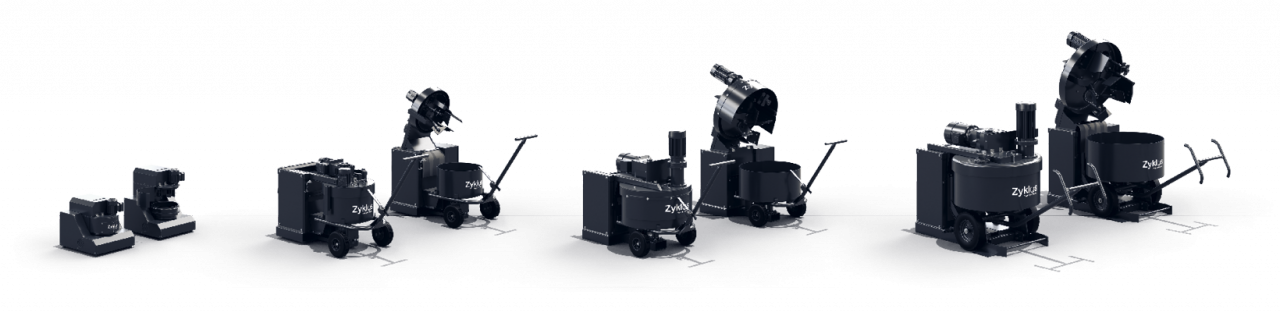

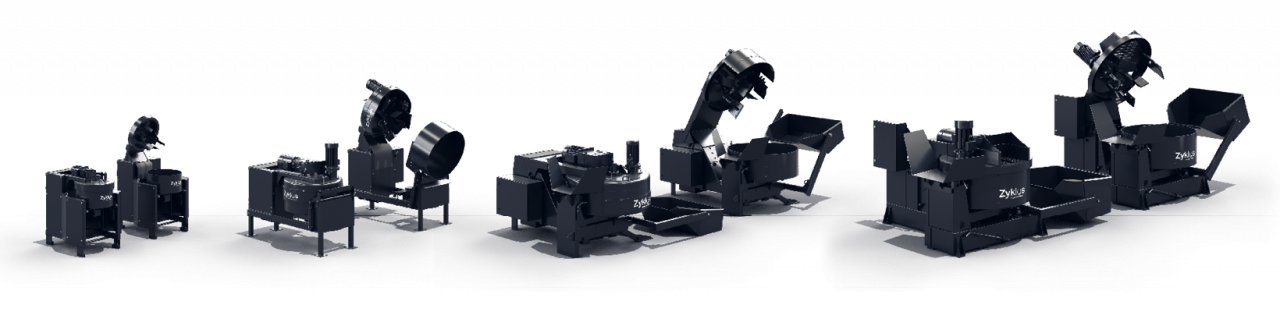

- Detachable mixing pan: The mixing pan is easily manual detachable.

- Mobile mixing pan: The mixing pan rests on a ball bearing turntable or is fix mounted on a trolley. Lifting and transportation of the mixing pan can be easy done by a trolley.

- Tiltable mixing pan: Tilting of the mixing pan is done electrically/hydraulically by push-button.

Discharge

- By tilting the mixing pan (ZK models)

- By detaching/moving the mixing pan (ZZ models)

Skip

- The models ZK 150 – ZK 500 can be equipped with a skip

Areas of application

All sorts of concrete:

- Lightweight, fibre, fine and polymer concrete

- Self-compacting and Ultra High Performance Concrete

- Mortar, plaster

- Concrete and artificial stones

- Exposed aggregate concrete

- Paving slabs

- Roof tiles

- Precast concrete parts such as coloured U-, L- and manhole stones

- Window and door lintels

- Prefabricated garages

- Internal/external concrete pipes

- Crane counterbalance weights

- Machine tool beds

- Spacer blocks for reinforced concrete

Further applications:

- Adhesives for tiles

- Floorings: Industrial or sports ground flooring

- Refractory and ceramic compounds

- Domestic pottery (flowerpots, etc.)

- Components made of technical ceramics, porcelain

- Roof tiles

- Glass

- Accumulator fillings

- Abrasives

- Foundry sand

- Insulating materials

- Fillers

- Chemical products

- Waste treatment

Zyklos models