Drive unit

- Heavy duty gear box

- Drive motor with 3 thermistor overload sensors Long service life with low maintenance cost

- Smooth operation

- Frequency converters for speed control

- Electronic soft start control to protect the drive elements

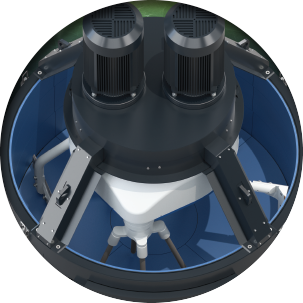

Mixing tools / whirler

- Protective coated mixer arm mountings and positioning elements

- Mixer and scraper arms on nylon lined bearings

- Spring steel mixer arms and mixer stars

- Wear sleeves

- Very long service life

- Mixing blades made of synthetics, hard cast steel or hard metal coated

The discontinuous whirler technology from Pemat

- Good distribution of the mix including fine grained materials

- Fast homogenisation

- Accurate repetition

- High energy efficiency

Discontinuous whirler

Example Planetary mixer PMPR

The independently controlled whirler technology from Pemat

- Excellent distribution of the mix including fine grained materials

- Ultra-fast homogenisation

- The greatest possible repetition

- Very high energy efficiency

- Frequency converters for speed control

Independently controlled whirler

Example Multimix Planetary mixer PMPM

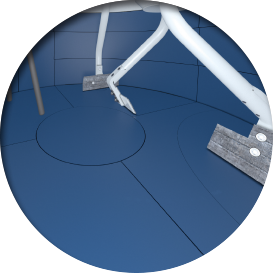

Mixing pan wear linings

Available in various materials:

- Steel plate

- Hardox steel plate

- Pemadur hard faced steel

- Special chill cast tiles

- Polyurethane

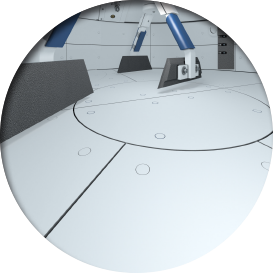

Protection cover

- Four large segments

- The individual segments can be opened easily either manually or by lifting systems

- Mixer safety device provide great operational reliability

- Special rubber sealing for dust free operation

- Generous inspection flap

Mixer safety device

Comprising of:

- Hinged protection cover segments

- Lateral inspection door

- Mixing process inspection flap

- Discharge protection

Discharge

- Hydraulically operated

- Fast clean discharge

- Up to 4 discharge outlets possible

- Part opening possible

- Discharge protection for health and safety

- Individual pivoting or telescopic discharge chutes with wear lining in steel, polyurethane or rubber

Accessories

- Skip hoists

- High pressure wash-out system

- Moisture metering

- Camera attachment

- Cooling / drying

Brochure / Technical details

Technical details: